Hello Everybody,

I'm new to this field as well as in CNC machining and I have a misunderstanding, let me explain

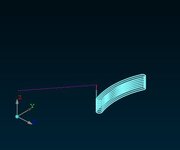

I'm trying to make a rounded machining of the width of my tool and when I export my toolpath it gives me the contour of my machining, So I've got a lot more machining to do than I'd like, I don't understand, could you tell me where is the problem?.

Thank's a lot for your answers

Below is the code generated by DXF2GCODE

(Generated with: DXF2GCODE)

(Version: Py3.11.1 PyQt5.15.8, Date: [imath]Date: Mon Feb 6 21:49:45 2023 +0100[/imath])

(Créé à partir du fichier: G:/Test.DXF)(Used Postprocessor: postpro_config.cfg)

(Output format description: G-CODE for LinuxCNC)

(Heure: Mon Oct 28 13:16:40 2024)G21 (Units in millimeters)

G90 (Absolute programming)

G64 (Default cutting) G17 (XY plane) G40 (Cancel radius comp.) G49 (Cancel length comp.)

G0 Z 15.000

(*** LAYER: 0 ***)

T1 M6

S10000

(* SHAPE Nr: 67 *)

G0 X 24.684 Y 30.153

M3

G0 Z 12.000

F150

G1 Z 7.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958 (why does it generate multiple lines?)

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 6.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 5.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 4.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 3.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 2.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 1.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 0.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 12.000

G0 Z 15.000

G0 X 0.000 Y 0.000

M30 (Program end)

I'm new to this field as well as in CNC machining and I have a misunderstanding, let me explain

I'm trying to make a rounded machining of the width of my tool and when I export my toolpath it gives me the contour of my machining, So I've got a lot more machining to do than I'd like, I don't understand, could you tell me where is the problem?.

Thank's a lot for your answers

Below is the code generated by DXF2GCODE

(Generated with: DXF2GCODE)

(Version: Py3.11.1 PyQt5.15.8, Date: [imath]Date: Mon Feb 6 21:49:45 2023 +0100[/imath])

(Créé à partir du fichier: G:/Test.DXF)(Used Postprocessor: postpro_config.cfg)

(Output format description: G-CODE for LinuxCNC)

(Heure: Mon Oct 28 13:16:40 2024)G21 (Units in millimeters)

G90 (Absolute programming)

G64 (Default cutting) G17 (XY plane) G40 (Cancel radius comp.) G49 (Cancel length comp.)

G0 Z 15.000

(*** LAYER: 0 ***)

T1 M6

S10000

(* SHAPE Nr: 67 *)

G0 X 24.684 Y 30.153

M3

G0 Z 12.000

F150

G1 Z 7.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958 (why does it generate multiple lines?)

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 6.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 5.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 4.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 3.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 2.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 1.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 0.000

F400

G2 X 25.805 Y 60.915 I 39.613 J 13.958

G2 X 28.554 Y 59.715 I 1.375 J -0.600

G3 X 27.513 Y 31.150 I 35.742 J -15.604

G2 X 24.684 Y 30.153 I -1.415 J -0.498

F150

G1 Z 12.000

G0 Z 15.000

G0 X 0.000 Y 0.000

M30 (Program end)

Anhänge

Zuletzt bearbeitet: